ADDITIONAL CAPABILITIES

TAILORED TO YOUR REQUIREMENTS • PHOENIX BUILDS TO MEET YOUR NEEDS

Phoenix also designs and manufactures machinery for special purposes for customers whose part design or production requirements cannot be met using standard machine tools. We utilize our many years of experience to provide our customers with machine solutions for a wide range of part and production volume requirements.

GRAPHITE MACHINING

To fulfill a customer’s unique design requirements, Phoenix designed its largest and most complicated machine to date. This machine, which is comprised of 3 stations, 24 axes, and a gantry robot loading system, centers rough and finish turns, and bores and threads graphite electrodes which are then used to melt steel. The part sizes range from 14” diameter and 72” long to 36” diameter and 140” long. Depending on the part being produced, the production rate for this system is 20 parts per hour. This engineering feat is a testament to Phoenix’s design and manufacturing capabilities.

GANTRY MILL

After seeing increased demand from customers whose machining needs extended beyond what a vertical machine was capable of, we built the first Phoenix Gantry Mill. Built to travel 480” front to back, 192” cross travel and 110” on the ram, this machine provided the ability to attack a part from multiple angles. With the inclusion of a 2-axis CNC universal head, the Gantry boasts a total of 5 axes, which allow for dynamic machining, while heavy-duty castings and clamping systems also deliver the toughness and rigidity to hold up to the high forces required to machine aggressively if needed.

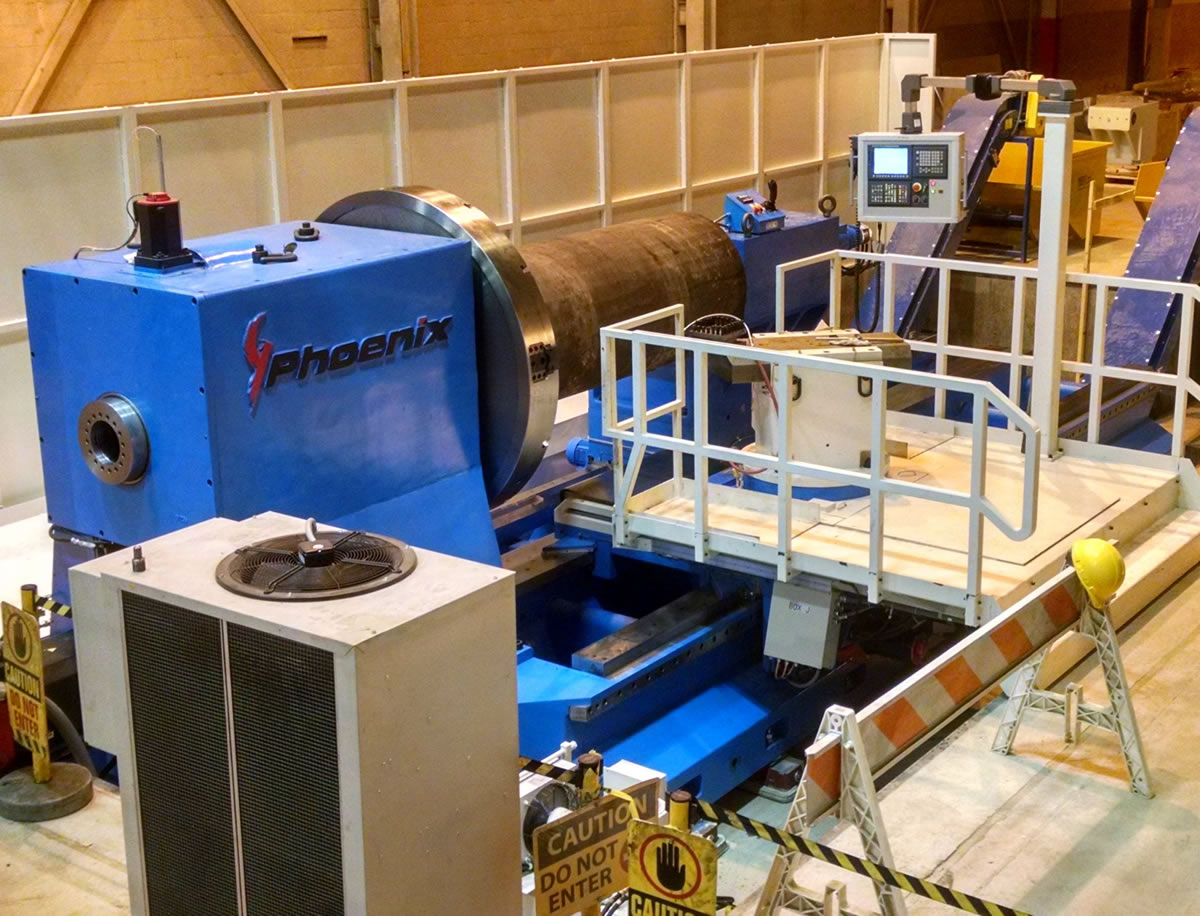

HORIZONTAL LATHE

When one of our longstanding customers determined they were in need of a specialty machine, they approached us first, referencing the confidence they had in Phoenix’s engineering and design abilities, knowing that we had not built a machine like this to date. The result was the premier of the Phoenix Horizontal Lathe. This machine featured a bed length of 240” and a 75” swing while allowing for turning, milling and boring operations. It was also designed with a “4-Way” bed construction, meaning that the compound slide, when fully retracted, can pass by the tailstock, providing increased flexibility particularly when loading parts.

TO LEARN MORE ABOUT OUR BUILD CAPABILITIES,

Contact Us at: 508-399-7100 or