COST EFFECTIVE VERTICAL TURNING CENTERS

VERTICAL TURNING CENTERS • TAILORED TO YOUR REQUIREMENTS

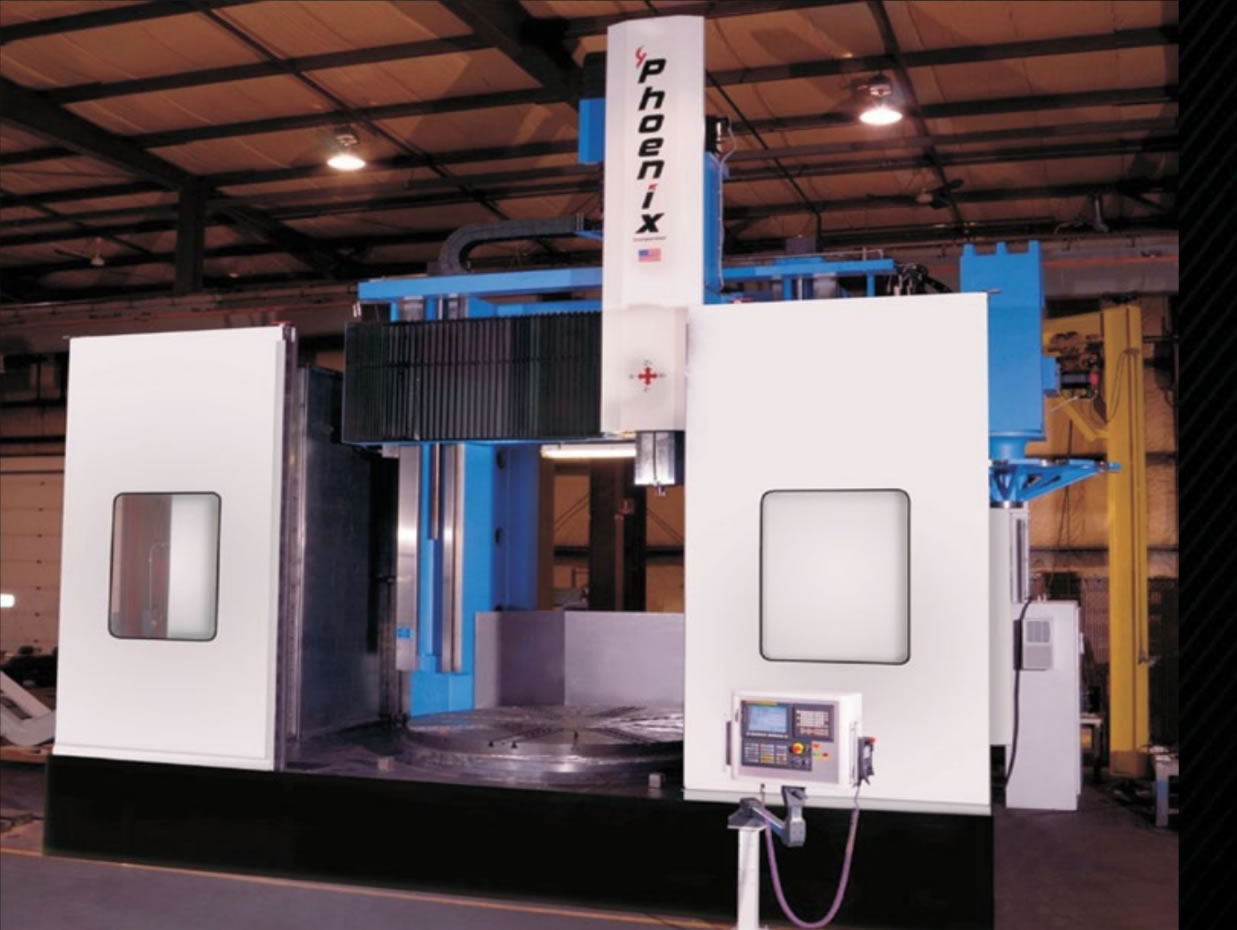

Designed for high machine stiffness and high precision repeatability, Phoenix Vertical Turning and Milling machines provide a tailored solution to your needs. Constructed with all cast iron and steel forgings and the best bearing support system in the industry, an exact repeatable cut is always guaranteed. Tailor-made to your part height and part swing requirements, Phoenix VTMC’s provide both flexibility and value. Depending on your application, add-ons such as pallet systems, 2-axis CNC heads, tool and part probing, and various tooling designs can be engineered for the machine as well.

Over the past 30 years, we have provided more large vertical turning and milling machines than any other manufacturer in the world. These machines have been used to make aircraft engine parts, bearings, heavy cast pump housings, nuclear pressure vessels and steam/gas turbine parts, among many other applications.

VTC-1000tc

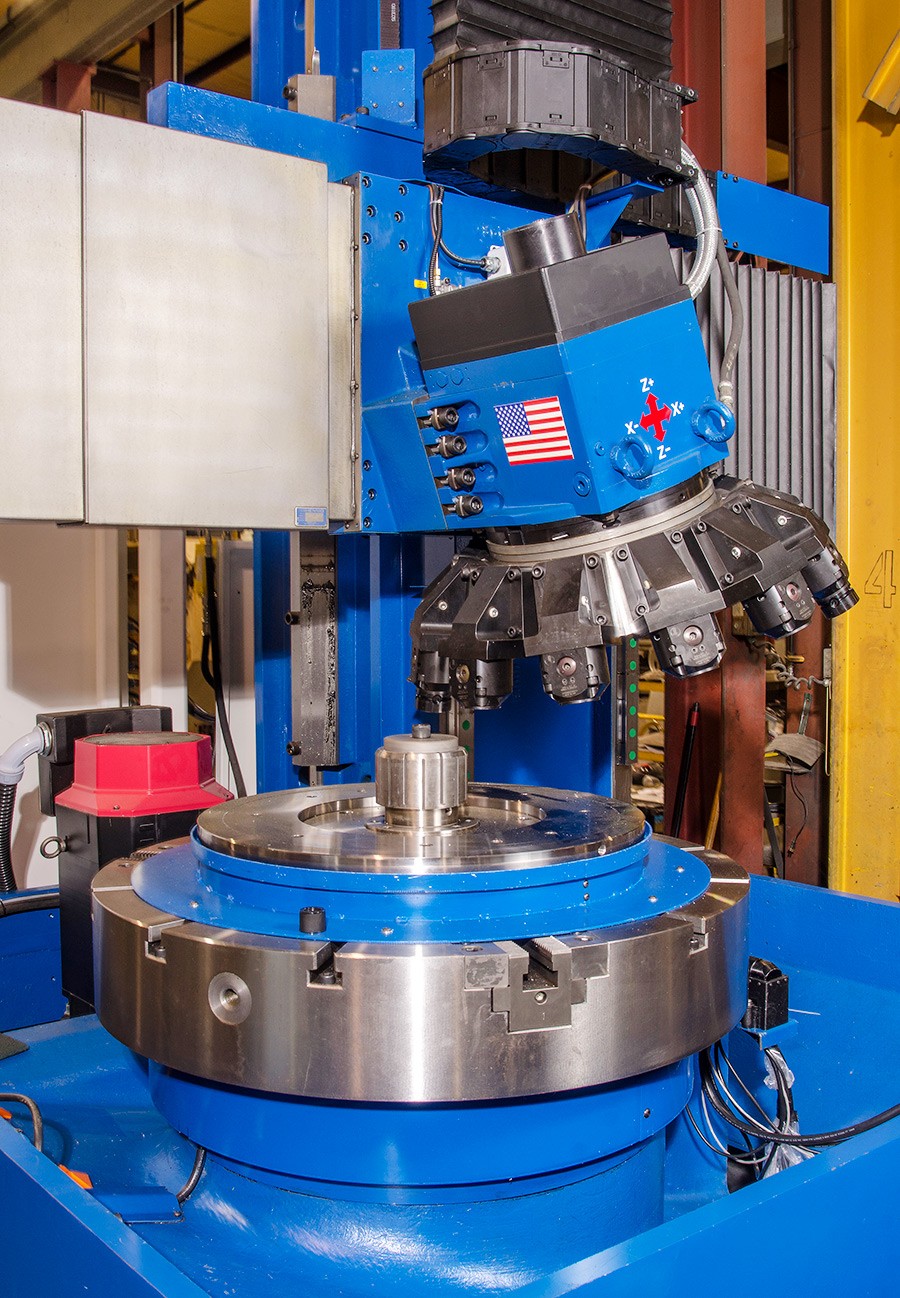

As we sensed the mounting demand, we created the 2nd generation of the VTC-1000, equipped with a ram and tool changer. This model eliminated the need for boring bars and hook tools, increased rigidity and allowed for deeper cutting depth. These machines have since been used for everything from aerospace parts to railroad wheels.

VTC-1500

The VTC-1500 expanded the line of compact machines by increasing swing, enabling the machine to handle a larger part diameter than previous models. Built with a 37-inch Ram and Xed Cross Rail, this machine is as robust as some that have a much larger footprint while sticking to the compact framework and cost-effective price point of the Phoenix compact vertical family.

COMPACT MACHINE SPECIFICATIONS

- Swing > 63 in.

- Cutting Dia. > 63 in.

- Table Dia. > 59 in.

- Tool Length > 12 in.

- Z-Axis Stroke > 37 in.

- X-Axis Stroke > 75 in.

HIGH PERFORMANCE MEDIUM-DUTY TURNING MACHINES

As an early entrant into the world of foam pattern technology, we’ve paired with some of the nation’s most respected foundries to create castings that are completely tailored for each individual machine, but also have the strength and durability to hold up to our customer’s machining needs. The ability to design components with foam pattern castings allows us to build machines in different sizes with a minimal impact on cost.

APPLICATIONS INCLUDE:

- Aircraft Engine Cases

- Large Turbine Disks

- Large Thrust Bearing Races

- Large Gear Blanks

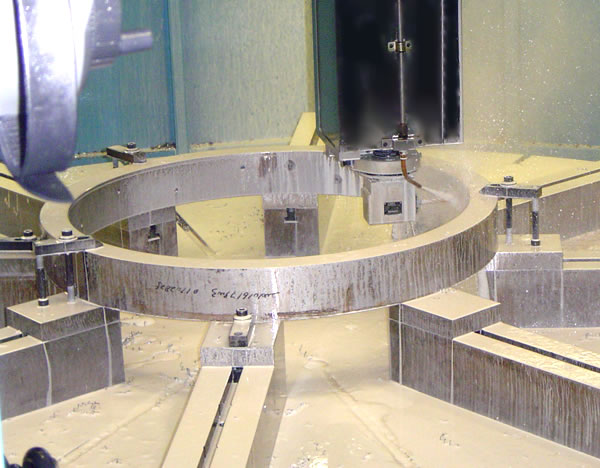

Our range of medium-duty machines is built with heavy-duty boxed ways, gibs and straps and feature the latest in cross roller bearing technology. These machines are often built with certain additions that our customers require including: pallet systems, 2-axis CNC heads, tool and part probing, and various tooling designs.

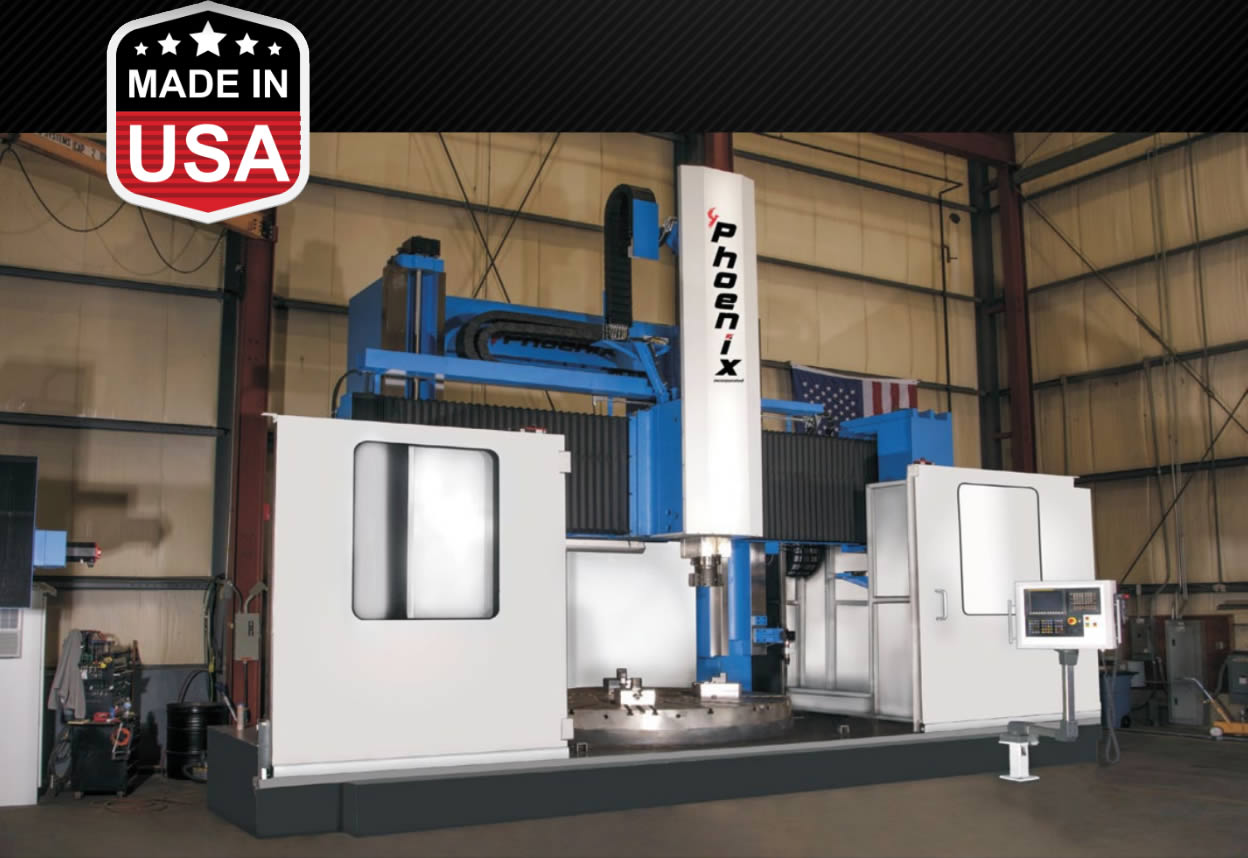

The Phoenix product line includes the largest vertical turning and milling machines manufactured in the U.S.

LARGE VERTICAL TURNING & MILLING MACHINES

Designed for high-machine stiffness and high-precision repeatability, the Phoenix Vertical Turning Center (VTC) provides a tailored solution to your turning needs. Constructed with all cast iron and steel forgings and the best bearing support system in the industry, an exact repeatable cut is always guaranteed.

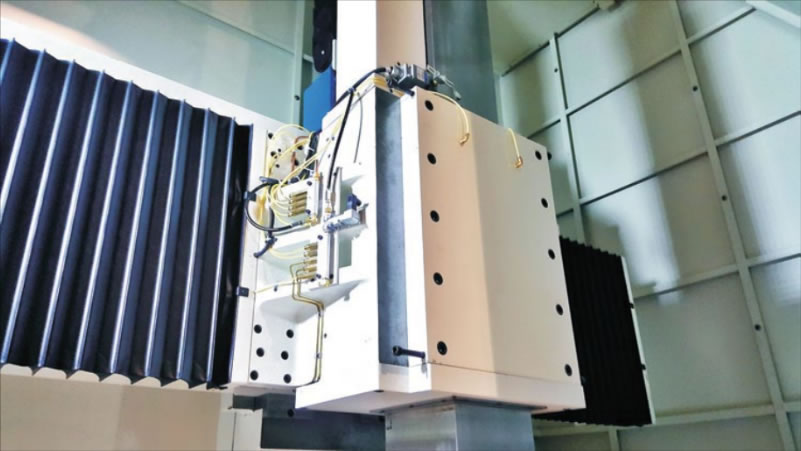

Custom-made to your part height and part swing requirements, the Phoenix VTC provides both flexibility and value. Depending on your application a second head can be added for milling, drilling or both. In addition, a customized pallet or gantry system is available to interface with your manufacturing floor.

FEATURES INCLUDE:

- Vertical Turning Centers up to 315″

- Fixed and Adjustable Rail Machines

- Cross Roller Bearing or Hydrostatic Table Support Available

Other design features of these machines include y-axis machining capability and floor-to-ceiling, stand-alone tool changers, which save substantial amounts of time and effort when changing tools on machines of this magnitude. With the machine operator in mind, we’ve also designed and developed state-of-the-art independent operator platforms for our largest machines. This allows for the same type of operational access and control as you’d find on machines a quarter of the size.

Vertical Milling and Drilling Machines

VERTICAL MACHINING CENTERS • VERTICAL MILLING CENTERS

Over the past 30 years, we have produced more large machines

than any other manufacturer in the world.

At the top end of our capabilities are some of the largest machines built in North America over the last 30+ years. Built with transmission speeds up to 150RPM and hydrostatic table bearings capable of supporting a table load capacity of 150 tons, these machines are truly equipped for the heaviest of turning operations.

APPLICATIONS INCLUDE:

- Large Turbine Cases

- Largest Aircraft Engine Cases

- Large-Diameter Aerospace Domes & Rings

- Heavy Roughing on Forgings

Vertical Milling and Drilling Machines

VERTICAL MACHINING CENTERS • VERTICAL MILLING CENTERS

Over the past 30 years we have provided more large machines

than any other manufacturer in the world.

At the top end of our capabilities are some of the largest machines built in North America over the last 30+ years. Built with transmission speeds up to 150HP and hydrostatic table bearings capable of supporting a table load capacity of 150 tons, these machines are truly equipped for the heaviest of turning operations.

APPLICATIONS INCLUDE:

- Large Turbine Cases

- Largest Aircraft Engine Cases

- Large Diameter Aerospace Domes & Rings

- Heavy Roughing on Forgings

- Part Height – from 72” to over 20′

- Part Swing – from 50” to over 25′

- Cutting Tool Ram – Able to provide different tooling configurations for Capto or KM tooling

- Tools Changer Magazine – from 12 to over 50 tools

- Table Mounting – Standard or power chuck

- Pallet System or Gantry System – Available

- High Pressure Coolant System – Available

- Spindle – Gear Driven from 22KW to 60KW horse power

- Cooling – Air or Coolant through the draw bar

- Table positioning – Provided through a Heidenhain high accuracy rotary encoder mounted directly in the table center

- Table Drive System – Controlled by 2 precision ground pinions driven by AC servo motors and planetary gearboxes

- Rail Leveling System – Servo controlled w/ hardened shelves and way support on both sides

- Ways – Hardened and ground not requiring linear guides

- Ram – 8”-14” square for reduced deflection and increased reliability

- Base and Rail – Class 35-40 cast iron for stability and vibration reduction

- Ball Screw – 3” diameter with 8 support bearings for large load capacity

- Tool Clamping – strongest and most reliable in industry

- High pressure coolant systems and special filtration systems

- Table Support – Cross roller bearing offering higher table speeds with slightly less load capacity or hydrostatic bearing which handles loads over 150 Tons depending on application

- Probing – Integrated Tool and Part Probing available

- Rail – Fixed for 48” tall parts or movable for parts 7” tall and greater

- Finite Element Analysis – To optimize strength and reduce weight

- Large mounting holes – Easily adapts to power chucks

- Tool Changer – Carrousel or Stacked for reduced footprint

TO LEARN MORE ABOUT OUR VERTICAL TURNING, DRILLING AND MILLING MACHINES,

Contact Us at: 508-399-7100 or