AEROSPACE AND AVIATION

In the Aerospace and aviation industries, large components have to be held to precise tolerances. Phoenix’s vertical turning centers and vertical machining centers lead this industry in precision machining on a large scale.

Our experience includes turning a 230” diameter dome used in the Delta rocket to a wall thickness of less than .125”. Many of our machines are used in the helicopter industry to mill the main hub where the blades attach and to also make other large diameter parts particularly for large, heavy-lift helicopters.

The dome shown above is made of aluminum, is 230” in diameter and is as thin as 1.125” when it is finished. There are also hundreds of drilled holes in the top and bottom flanges. The outside of the dome is pictured, but the inside of the dome is also machined in a previous setup. Part weight is critical and therefore wall thickness must be maintained. This machine is also equipped with a 2-axis tilt/rotary head under CNC control to allow drilling and tapping of holes at an angle to the X-Y-Z coordinate system. The machine pictured is an adjustable rail vertical turning/milling center.

AIRCRAFT ENGINE MANUFACTURING

Precision is key in the manufacturing of aircraft engines and Phoenix’s industry leading rigidity and repeatability specifications can handle your requirements. Building on our years of experience we can provide exactly what you need − no more and no less.

Casings

Regardless of the material; Inconel, Rene, Titanium or new composites, the round fragile cases surrounding the different sections of the engine can be machined by Phoenix. The machining requirements for these components include shallow I.D and O.D. turning as well as facing on both ends. Phoenix’s vertical turning centers and vertical milling centers are ideal for the turning and milling operations on large diameter commercial engine components.

Blades and Vanes

The airfoils of turbine blades, up to 16” wide and 72” long, have been machined four at-a-time using Phoenix’s multi-spindle Airfoil Milling machines. On the other end of the spectrum, Phoenix designed small “lean friendly” 4-axis lathes to turn the ends of nozzles measuring less than .375” in diameter.

Disks

The center disks which hold the vanes and blades must be completely machined. Phoenix’s vertical turning centers can do the majority of this. The dovetails slots holding the vanes or blades are machined using the Phoenix horizontal broaching center with its up to four cutting rows and 380” travel.

INDUSTRIAL POWER − NUCLEAR, GAS AND STEAM

The power generation industry requires machines capable of both large swings and tall part heights. With a product line that includes table sizes of up to 420” and a height under the cross rail of up to 192”, Phoenix’s vertical turning centers are the ideal solution. In addition, our horizontal broaching machines, with strokes up to 380” and up to four rows of tooling, have proven to be an excellent choice for broaching slots.

Nuclear

Our largest and tallest vertical turning centers and vertical turning and milling centers are used to machine larger nuclear pressure vessels and pump housings. We have provided machines with a maximum part height of up to 192” and a maximum swing of up to 35′ (420”) for this industry. Our movable rail machines are ideally suited for these applications.

Gas and Steam

Large turbine wheels are machined on both our fixed-rail and adjustable-rail vertical turning centers. Our large horizontal broaching machines are used to broach the slots in these turbine disks. Our multi-spindle blade milling machines have been machining the airfoils of large turbine blades for over 15 years.

WIND POWER

Due to their size, windmills require machining done on a large scale. Phoenix’s lines of vertical turning, milling and drilling centers meet the needs of the wind power industry.

Bearing Races

Our customers are using Phoenix’s vertical turning centers and vertical drilling centers to turn, drill and tap windmill bearing races. The low height requirements of these bearings are ideal for our fixed rail VTC and VMC models. The turning and drilling can be done on both the inner and outer diameters of the bearing races. Depending on your production process, the turning and drilling can be done on the same machine using combination live/turning rams or on separate machines dedicated to either turning or drilling.

For customers who grind their bearing races, our vertical grinding centers are ideal for this operation.

Tower Section Flanges

The turning, drilling and tapping of the windmill towers sections is also perfectly suited for Phoenix’s vertical turning centers and drilling centers.

Gears

Our gear gashing products are perfectly suited for machining the inner or outer diameter gear teeth of the bearing races.

GRAPHITE MACHINING

Whether you are completely machining large 3-ton graphite electrodes or adding grooves to graphite cathodes, we can make a machine to fit your needs. Phoenix’s ingenuity and willingness to take on challenges has let us enter this market where others would not. Give us your requirements, and we will make them a reality.

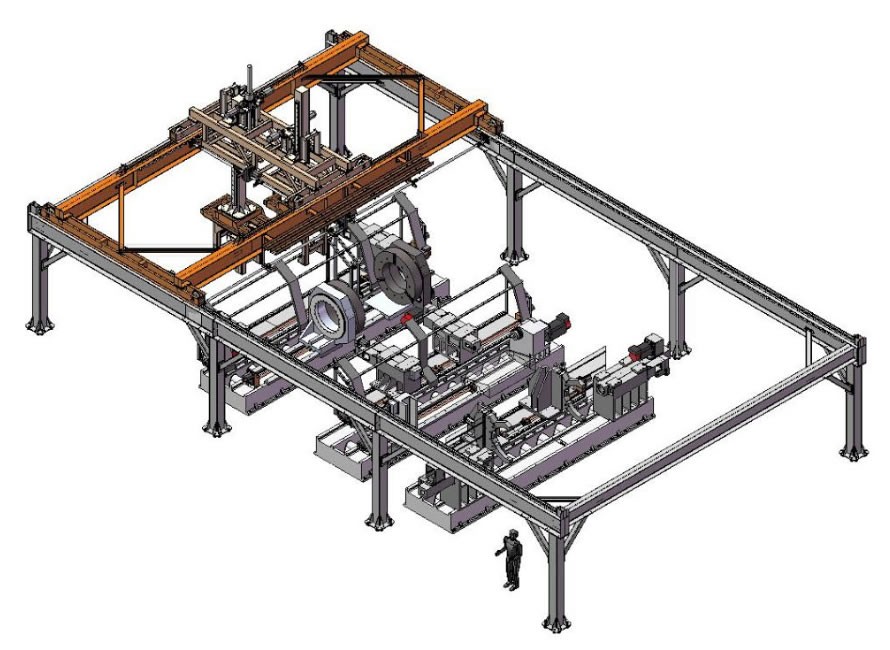

3-Stage Electrode Finishing Machine

The electrode finishing machine shown to the left includes three machining stations and an overhead gantry robot that moves the electrode through the system. The rough electrodes are centered with a best fit on the rough OD in station 1, rough and finish turned in station 2 and finally the sockets and end faces are machined in a single setup on station 3.

Cathode Machining

Cathodes can be machined on all sides in two setups using a special Phoenix multiple-head gantry milling machine.

MINING INDUSTRY

Mining equipment by nature is big and requires large machines to handle the crushing, feeding, grinding, pumping, transporting and processing of iron ore and other minerals. Phoenix makes constructing this equipment possible with our vertical turning and milling centers. From turning a 12′ road wheel to a 110,000 lb integral mill head everything is possible. Depending on your milling and turning needs our standard capabilities of up to 280” swing or our highly specialized 45′ diameter table will meet your needs.

Pump Casings

Phoenix adjustable rail vertical turning and vertical turning/milling centers are used to manufacture of large pump housings, as well as the impellers used to power the pumps. These pumps are used in both the mining and dredging industries.

Milling Heads

Milling heads can be both turned and milled on our large 45′ diameter fixed rail vertical turning/milling centers equipped with hydrostatic bearings to support part weights of up to 500,000 lbs.

BEARING MANUFACTURING

Our customers are using Phoenix’s vertical turning centers and vertical drilling centers to turn, drill and tap large bearing races used in the construction, medical and wind turbine industries. For the low height requirements, a fixed rail is ideal. The turning and drilling can be done on both the inner and outer diameters of the bearing races. Depending on your production process, the turning and drilling can be done on the same machine or separate machines.

Gears

The gear gashing products are perfectly suited for gashing the inner or outer diameter gear teeth of the bearing races.

TO LEARN MORE ABOUT OUR MACHINES AND SERVICES,

Contact Us at: 508-399-7100 or